Designed with Vision - Built with Precision

Arditi Collection crafts luxury furniture that tells a story a story of visionary design, material mastery, and artisanal precision. From bold statement pieces to immersive interior experiences, every creation is guided by a deep respect for form, proportion, and elegance.

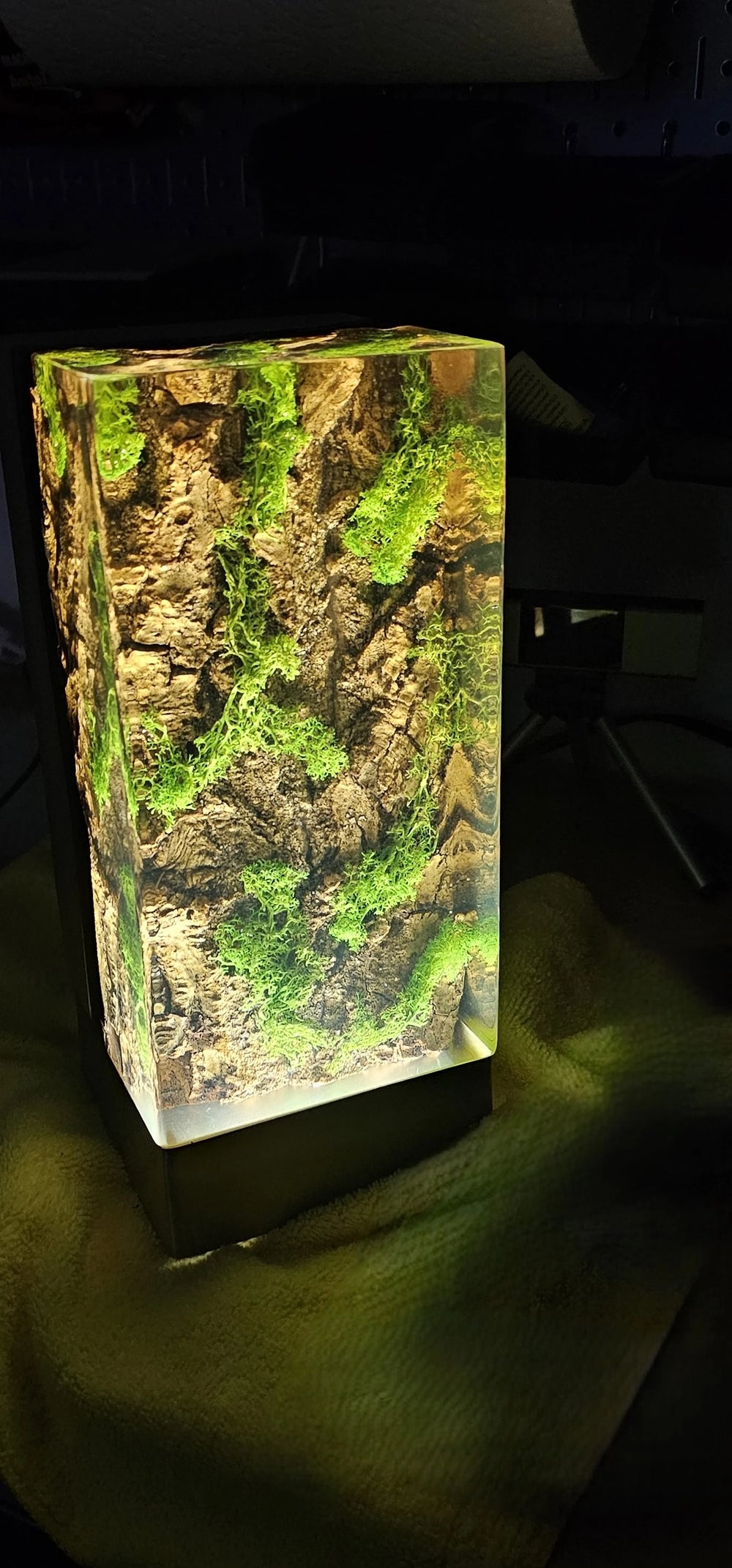

Our collections begin with rare materials: 300 year old Anatolian walnut, exotic veneers, high gloss resins, and sculptural metals each selected for their natural character and expressive potential. These elements are shaped using advanced techniques like PVD titanium coating, metal resin artistry, and mirror polish lacquers to transcend traditional limits of craftsmanship.

Every detail is intentional. Every finish is bespoke. Whether you're shaping a singular focal point or an entire residence, we invite you to explore a new dimension of timeless design tailored with vision, engineered for permanence, and destined to inspire.

Projects

Arditi Works

At Arditi Works, every project is a seamless fusion of artistry, innovation, and precision. From the bold textures of natural stone to the warmth of fine wood and the elegance of custom finishes, we craft spaces that transcend trends timeless environments where luxury meets purpose.

PARTNER WITH US

Collaborate with Arditi Collection to bring distinctive environments to life.

We work alongside architects, interior designers, and development teams worldwide, providing custom furniture solutions for both residential and project-based design.

From private residences to large-scale architectural spaces, our approach combines bespoke manufacturing, material-driven design, and seamless collaboration tailored to professional workflows.

Join our Trade and Real Estate Programs and explore a partnership built on craftsmanship, flexibility, and design-led execution.

Let’s bring extraordinary spaces to life together.

The Spirit Behind

Arditi Collection is a luxury furniture studio where design vision and material mastery converge. Our passion lies in crafting exceptional pieces that transcend function becoming sculptural statements that define spaces and reflect individuality.

We work with an elevated palette of premium materials: from 300-year old solid walnut and rare stones to lacquered finishes, Italian leathers, and bespoke fabrics. Every element is chosen not just for its beauty, but for its character, harmony, and timeless appeal.

Our signature lies in innovation. Techniques like metal resin fusion, PVD titanium coatings, and ultra high gloss lacquer systems allow us to achieve both artistic fluidity and architectural durability creating furniture that is bold, refined, and engineered to endure.

ach piece is made to order. Each project is shaped by dialogue. Whether you’re designing a statement table or curating an entire interior, we collaborate with architects, designers, and visionary clients to bring ambitious ideas to life with precision, care, and purpose.

"We don’t just build furniture — We shape legacies."

"We don’t just build furniture

We shape legacies"